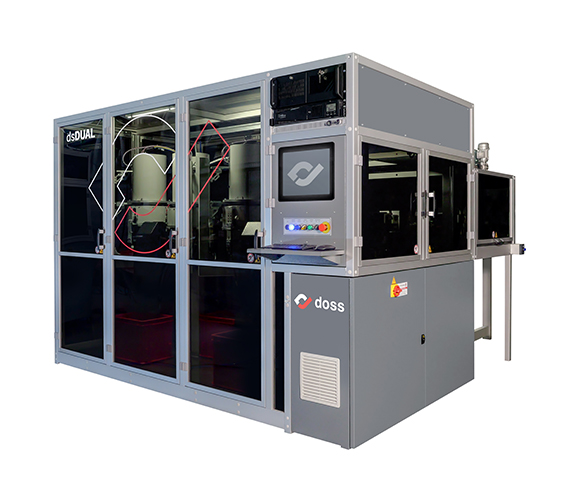

dsDUAL

Reliability²

Thanks to its dual table, dsDUAL guarantees inspection of both sides of the part under the same conditions.

The multiple configuration options available allow it to satisfy all analysis requirements.

- INSPECTION OF BOTH SIDES OF THE PART UNDER THE SAME CONDITIONS

- SATISFIES ALL ANALYSIS REQUIREMENTS

- DETECTS UP TO 7 NON-CONFORMITIES

- SUITABLE FOR ANALYZING A WIDE RANGE OF SIZES

Inspections

- Flatness

- Profile for detecting flashes and incomplete fills

- Dimensional

- External and internal surfaces

- Presence of cuts, fractures, and bubbles

Standard equipment

- Top Surface Station

- Bottom Surface Station (direct)

- Barrel Laser

- Peripheral 8-sided pyramidal station

- Up to 7 supported inspection stations

- Up to 7 exits for non-conformities

- Feed system with elevator and loading conveyor belt

- Various packaging options available

- Various feed systems to choose from

Optional

- Metal detector

- Multishot

- 4-view peripheral

- Radial station

- Telecentric lens

- Squeezer station

- Pin-Hole optics

- P-P Laser

Description

An automatic sorting machine composed of two semi-transparent glass tables that makes it possible to inspect both sides of parts with the use of a mechanical flipper. The material to be sorted is loaded through a feed system that is capable of handling items of various sizes and materials.

The operator sets the parameters and tolerances that must be respected and the system generates a report on the compliant parts, details regarding defective parts, and statistical reports.

The machine is available in versions with a 5 or 12 megapixel camera, with or without a motorized optical system (zoom, focus, aperture).

- Statistics and reports

- Batch traceability

- Remote management

- Interacts with management software (M.E.S.)

-

FEEDING SYSTEM

Parts are loaded into the machine by the loading systems.

-

INSPECTION UNITS

Parts pass throught various units (superficial, peripheral or laser station) by rotating table, or belts, or pick & place system.

-

SOFTWARE ELABORATION

Software inspects the images of the parts taken by the inspection units.

-

PARTS REJECTION

If defect are detected parts will be rejected.

-

‘GOOD’ PART COLLECTION

If partes pass all controlled parameters, they will be collected in ‘good’ bin or packing system.

Technical characteristics

Items/Parts

| Type of Parts | Elastomers, rigid materials |

| Color | All, not transparent |

| Parts Inspected | O-rings, technical parts |

| Characteristics | Clean, free of dust that could alter the part’s surface |

| Size | Various ranges available between 5 – 110 mm OD |

| Chord/Height | 0.8 – 15 mm |

VISION

| Resolution | Depends on the configuration |

| Zoom | Option available |

| Type of Camera | Matrix |

| Maximum Framed Field | 120 mm |

| Camera Resolution | 5 o 12 MP |

CHARACTERISTICS

| Speed | Up to 10 pts/s |

| Load | Automatic |

| Type of Machine | Dual-table |

| Noise Level | < 75 ㏈ |

| Three-Phase Power Supply | 230 – 480 v |

| Maximum Installed Power | 4 Kw |

| Average Consumption | 1.7 Kw |

| Compressed Air Consumption | 600 NL/Min |

Size

Request information

For more information about our company or products, or if you have a question or require clarification, call us or fill out the form located next to this message. Our staff will get back to you as soon as possible.

Call us

Or write to us