dsONE

All that you need

dsONE meets all inspection needs thanks to the many types of stations available, while maintaining a compact design.

- THOROUGH INSPECTION

- DETECTS UP TO 3 NON-CONFORMITIES

- INSPECTS NON-FLIP COMPONENTS AS WELL

- TAKES UP LITTLE SPACE

Inspections

- Flatness

- Profile for detecting flashes and incomplete fills

- Dimensional

- External and internal surfaces

- Presence of cuts, fractures, and bubbles

Standard equipment

- Top and Bottom Surface Stations

- Barrel Laser Station

- Peripheral 8-sided pyramidal station

- Up to 5 supported inspection stations, one of which optional

- Up to 3 exits for non-conformities

- Feed system with elevator and loading conveyor belt

- Various packaging options available

- Various feed systems to choose from

Optional

- Metal detector

- Multishot

- 4-view peripheral

- Radial station

- Telecentric lens

- Squeezer station

- Pin-Hole optics

- P-P Laser

Description

Single-table automatic sorting machine for inspecting both sides of parts. This solution allows for optical inspection of parts through transparent glass and therefore without the need to flip them mechanically.

The system, with a simple and compact structure, is equipped with high-resolution cameras and a high-performance loading system capable of handling items of different sizes and materials. dsONE is also equipped with a Smart Software that allows for the fully automatic adjustment of parameters and images.

- Statistics and reports

- Batch traceability

- Remote management

- Interacts with management software (M.E.S.)

-

FEEDING SYSTEM

Parts are loaded into the machine by the loading systems.

-

INSPECTION UNITS

Parts pass throught various units (superficial, peripheral or laser station) by rotating table, or belts, or pick & place system.

-

SOFTWARE ELABORATION

Software inspects the images of the parts taken by the inspection units.

-

PARTS REJECTION

If defect are detected parts will be rejected.

-

‘GOOD’ PART COLLECTION

If partes pass all controlled parameters, they will be collected in ‘good’ bin or packing system.

Technical characteristics

Items/Parts

| Type of Parts | Elastomers, rigid materials |

| Color | All, not transparent |

| Parts Inspected | O-rings, technical parts |

| Characteristics | Clean, free of dust that could alter the part’s surface |

| Size | Various ranges available between 5 – 80 mm OD* |

| Chord/Height | 0.8 – 15 mm 0.8 – 25 mm (customized settings) ** |

VISION

| Zoom | Option available |

| Type of Camera | Matrix |

| Framed Field | From 5 to 90 mm* |

| Camera Resolution | 5-12 MPX |

CHARACTERISTICS

| Speed | Up to 10 pts/s |

| Load | Automatic |

| Type of Machine | Single-table |

| Noise Level | < 75 ㏈ |

| Three-Phase Power Supply | 230 – 480 v |

| Maximum Installed Power | 4 Kw |

| Average Consumption | 1.2 Kw |

| Compressed Air Consumption | 400 NL/Min |

* TOP view ** Custom

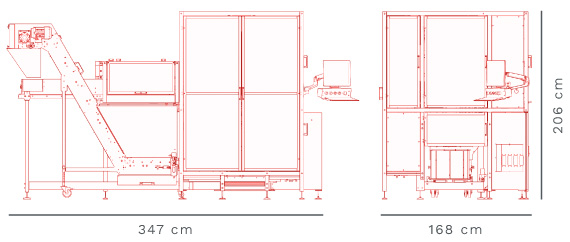

Size

Request information

For more information about our company or products, or if you have a question or require clarification, call us or fill out the form located next to this message. Our staff will get back to you as soon as possible.

Call us

Or write to us